Core Vertical Integration

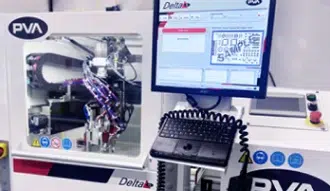

The Core Systems assembly process is the final stage in engineering rugged products for military and industrial applications. Our assembly services include system integration, robotic potting, conformal coating, and touch screen/AR glass

integration, ensuring high-quality, durable solutions built to withstand extreme environments.

Designed For You

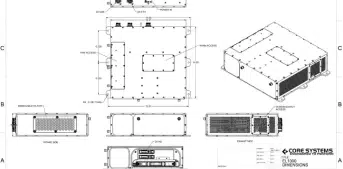

Custom Solutions

The design & engineering teams at Core Systems provide the experience you need to solve the many challenges of your mission. Start working with us today and leverage the Core Systems engineering expertise to create your next rugged solution that is application-specific and ready for action.

- Quick Turnaround

- Collaborative Process

- Data-Driven Results

Integration Process

Design & Engineering

Shipment Plan

We give you an estimated time of completion so you can begin planning ahead.

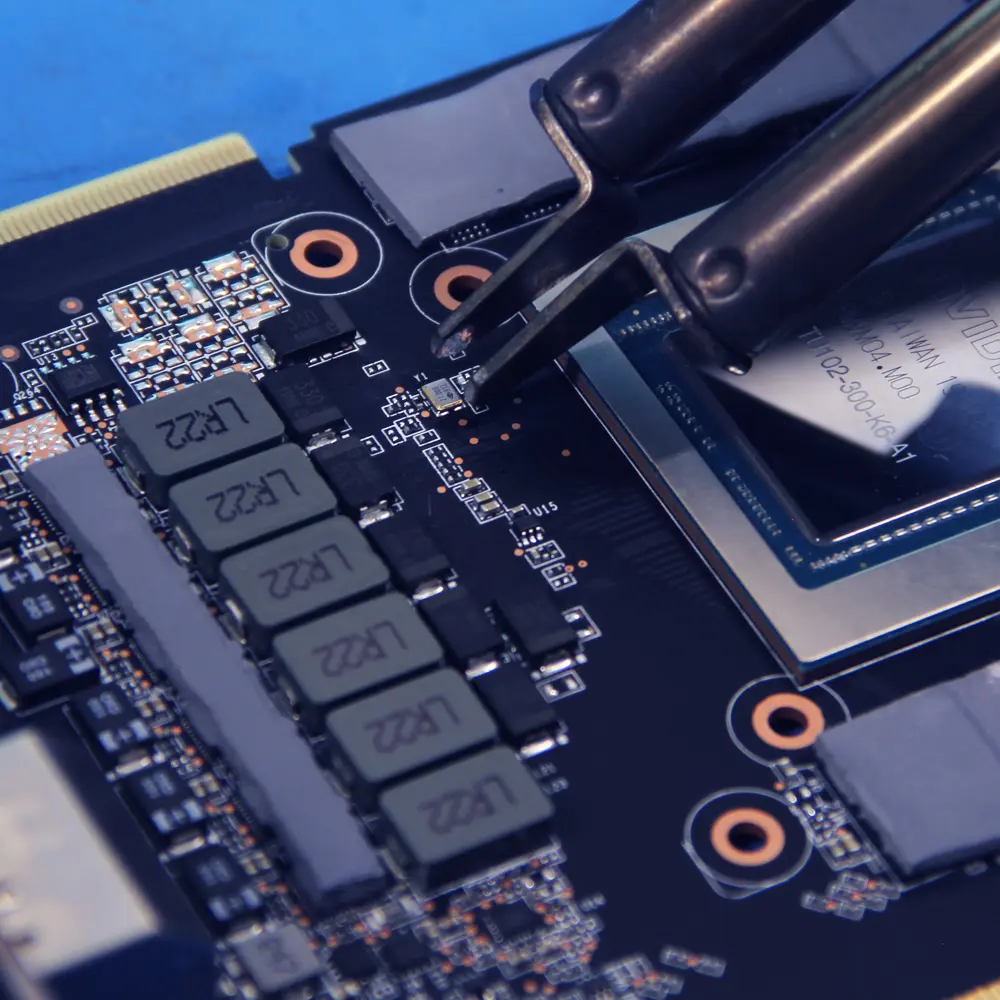

Coating & Potting

Our facility at Core Systems has the requirements to ensure all components are long-lasting.

Burn-In Rack

We push your system to the limit with a range of stress tests that guarantee high-octane computing for your mission.

Final Touches

We review and finalize all systems with complete reports that provides our customers with a guarantee of service.