Design to Assembly

Core Systems Engineering Services provide a complete suite of solutions for cradle-to-grave rugged product design and support. Our vertically-integrated manufacturing facility located in the US features industry leading design engineers, metal fabrication, CNC machining, environmental test lab and high volume product assembly on-site.

Contact Us

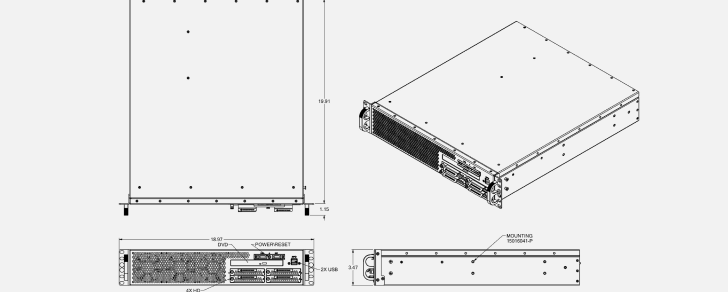

Custom Design

Purpose-Built Solutions

Our Engineering team specifically trained in small form factor mission computing, rugged displays, and rugged rackmount computing for quick turn applications.

- Concept Drawings

- Prototypes

- Custom – Metal

- Design Reviews

Fabrication

Metal Shop Onsite

Core Systems controls the entire manufacturing process, from sheet metal and CNC fabrication to metal finishing and final assembly, all at our San Diego headquarters.

- CNC Matching

- Laser Cutting

- Press Brakes

- MIG/TIG Welding

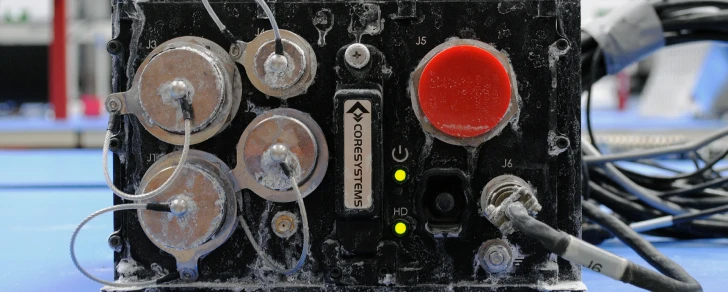

MIL-SPEC Testing

Testing for MIL-STD-810 & Beyond

Our environmental test lab at Core Systems HQ tests your design in real conditions, ensuring performance and accelerating the manufacturing process.

- High/Low Temperature

- Shock Vibration

- EMI/EMC

- Altitude

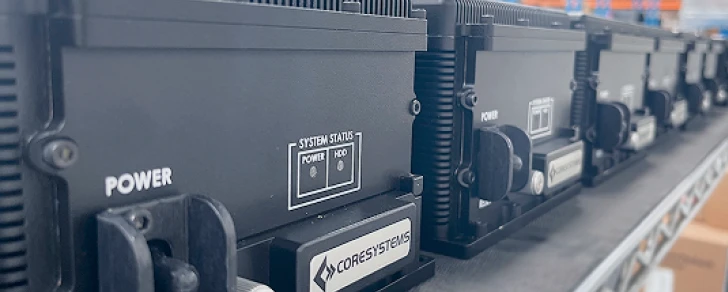

Assembly

Vertical Integration

Our assembly process includes system integration, robotic potting, conformal coating, and touch screen/AR glass integration, all done on-site in our clean room.

- Burn – In Rack

- Conformal Coating

- Robotic Potting

- Multiple Integration Floors

Enhanced Services

We engineer all of our products in the USA at our San Diego Headquarters

Powder Coating

Each Core Systems customer can rest assured that their rugged system is comprised of the highest quality components that have been proven through direct field deployment.

Laser Marking

We use precision laser marking for permanent, high-contrast labels that withstand extreme environments. Ideal for military, aerospace, and industrial applications, our markings ensure durability, compliance, and tamper resistance.

Custom Software

Our Sales Engineering and Systems Engineering staff is the best in the business and will walk you through every step of the manufacturing process from concept to production.

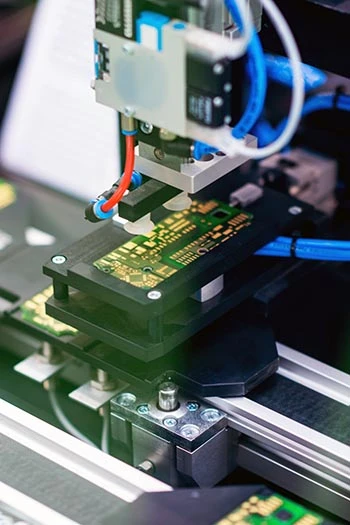

Robotic Potting

To protect circuit boards from shock and vibration, our Robotic Potting applies epoxy gel to critical points of the board precisely where it is needed.

Conformal Coating

All our boards receive a thin polymeric film which ‘conforms’ to the contours of a printed circuit board to protect the board’s components to act as protection from the elements.

Silk-Screening

Our ability to print on a wide variety of materials and the inks we use, comply with Military, Aerospace and Industrial specifications for permanent adhesion.