Core Systems Design Services

Core Systems leads the nation in Custom and Semi-Custom enclosure and integrated server design. We produce both commercial COTS enclosures and fully customized MIL-Spec hardened enclosures for specialized applications. The Core Systems engineering team are experts in edge computing, tactical computing, SFF servers, rackmount/panelmount LCD KVM designs and embedded military computers. We design and fabricate all products at our U.S.-based manufacturing facility. Call to speak to one of our Sales Engineers to design your next custom computing solution.

Contact Us

Custom Projects Gallery

Proven Designs for a variety of applications

Rugged Cisco 24-Port Switch

Dual Xeon Rugged Laptop

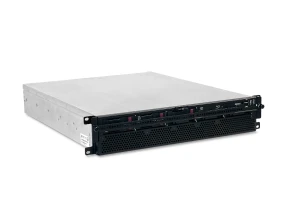

Rugged 2U HPE DL360RS

3U Rugged HPE Apollo Server

SFF Tactical Server

Rugged Console Computer KVM

FlyAway Case Server Stack

Rugged Cisco 8851 IP Phone

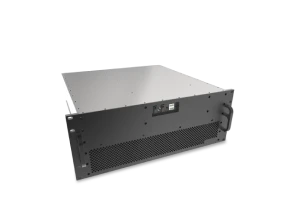

4U Rugged Server 3 GPUs

2U Dell Rugged Server

IP68 Bridge Server

IP68 Display and Computer

Rugged Xeon Laptop

Portable Computer with Touchscreen

Portable Dual CPU Computer-17″ Touch

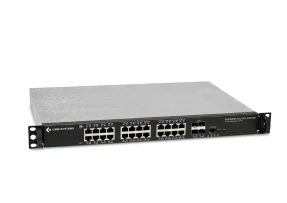

Rugged Cisco 48-Port switch

4U Rugged Dell Server

Rugged 20.1″ Display

4U 16″ Depth Rugged Server

4U Rugged Quad Xeon Server

4U Rugged 18″ GPU Server

4U 17″ Rugged Server

4U 16″ Rugged Server

4U High Altitude Server

3U 18″ Rugged Server

3U Telemetry Server

2U Server with Front Touchscreen

2U Rugged Cisco CGR

2U Cisco Rugged 48-Port Switch

CS221S-4948E

2U 20″ Rugged Server

2U Rugged Server M223

2U 20″ Rugged Server M22202

19″ Layflat LCD KVM

1U 7″ Depth Rugged Server

1U 19″ Depth Rugged Server

Case Studies

Proven Designs for a variety of applications

Rugged Mission-Ready Networking

The proven reliability of the hEX router has been transformed into a rugged military-grade solution, engineered for harsh field conditions and tactical deployments. Built into a hardened enclosure compliant with MIL-STD-810 and designed for extreme shock, vibration, and temperature fluctuations, this upgraded unit doubles the performance of the original — now featuring 512 MB of RAM and a modern ARM dual-core processor for high-speed data routing in mission-critical applications.

M318 3U Rugged Server 18″ Depth Chassis

Built in collaboration with L3 Harris Technologies, the M318 3U server is engineered for rugged, mission-critical deployments. It combines industrial-grade durability with a powerful 6-core Intel i7 CPU, legacy I/O, and modern features like dual redundant power supplies, TPM 2.0, and serial/GbE connectivity. Designed for embedded field use in defense, aerospace, and mobile command systems, the M318 is MIL-STD-461 compliant, conformal coated, and housed in a drip-resistant chassis. It delivers reliable computing power wherever the mission goes.

Upgraded M222 for Mobile Radar Platforms

Core Systems recently delivered a custom upgrade to the rugged M222 server for a client developing mobile, multi-object tracking radar platforms. These next-gen systems require powerful, reliable computing in extreme environments—making the customized M222 the ideal foundation for their latest plug-and-play, field-deployable solution. This collaboration exemplifies our commitment to delivering application-specific, rugged computing solutions that empower our clients to push the boundaries of technology.

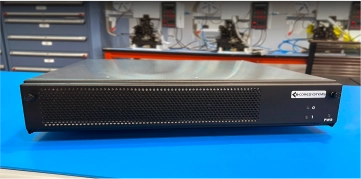

Custom 1U Rackmount Server for Defense and Mission Systems

This custom 1U server, designed in collaboration with Lockheed Martin, is engineered for seamless deployment in space-constrained and secure defense environments. Featuring a high-efficiency Intel Core i7 processor, robust I/O, onboard TPM, and custom rear I/O panel, this semi-rugged server provides flexible compute power for mission systems, signal processing, or training platforms. Its potting and hardening enhancements ensure reliable performance under variable field conditions.