Industrial system integration does not fail because teams lack expertise.

It fails because complexity compounds silently.

A power interface assumed compatible.

A control protocol not fully validated.

An environmental variable underestimated.

A compliance factor reviewed too late.

At first, everything appears aligned.

Then integration begins.

Then friction surfaces.

Then timelines shift.

At Core Systems, we approach integration differently. We engineer predictability into complex industrial and defense-aligned environments by removing ambiguity before deployment.

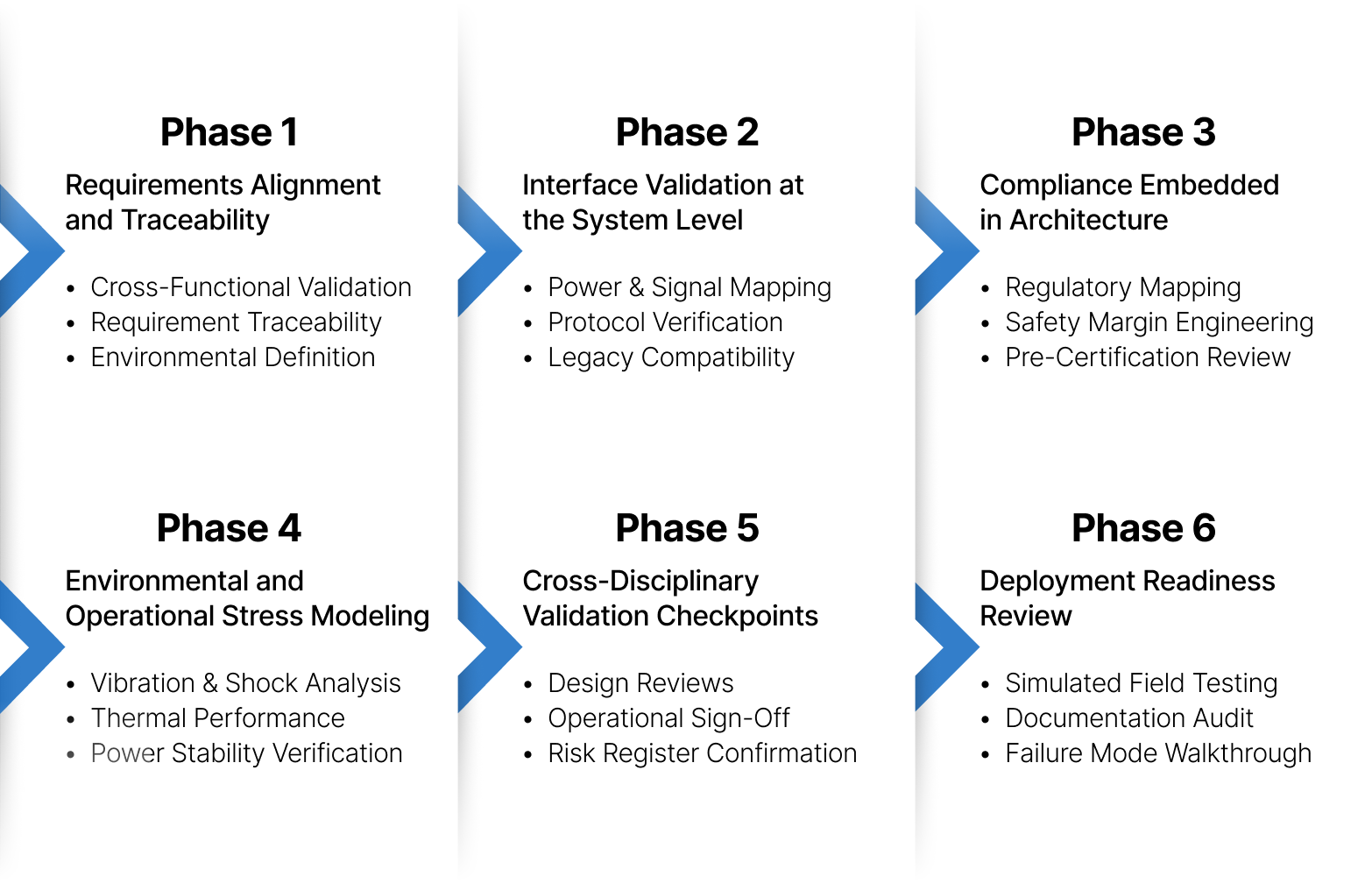

This checklist reflects the structured integration methodology we apply across high-reliability programs.

As you review it, you may begin to notice where hidden exposure could be forming inside your own systems.

Before hardware is finalized or integration begins, clarity must exist at the architectural level.

✔ Confirm cross-functional requirement alignment

Electrical, mechanical, controls, compliance, and operational teams must validate performance expectations together.

✔ Establish requirement traceability

Every requirement must map directly to a design element and verification method.

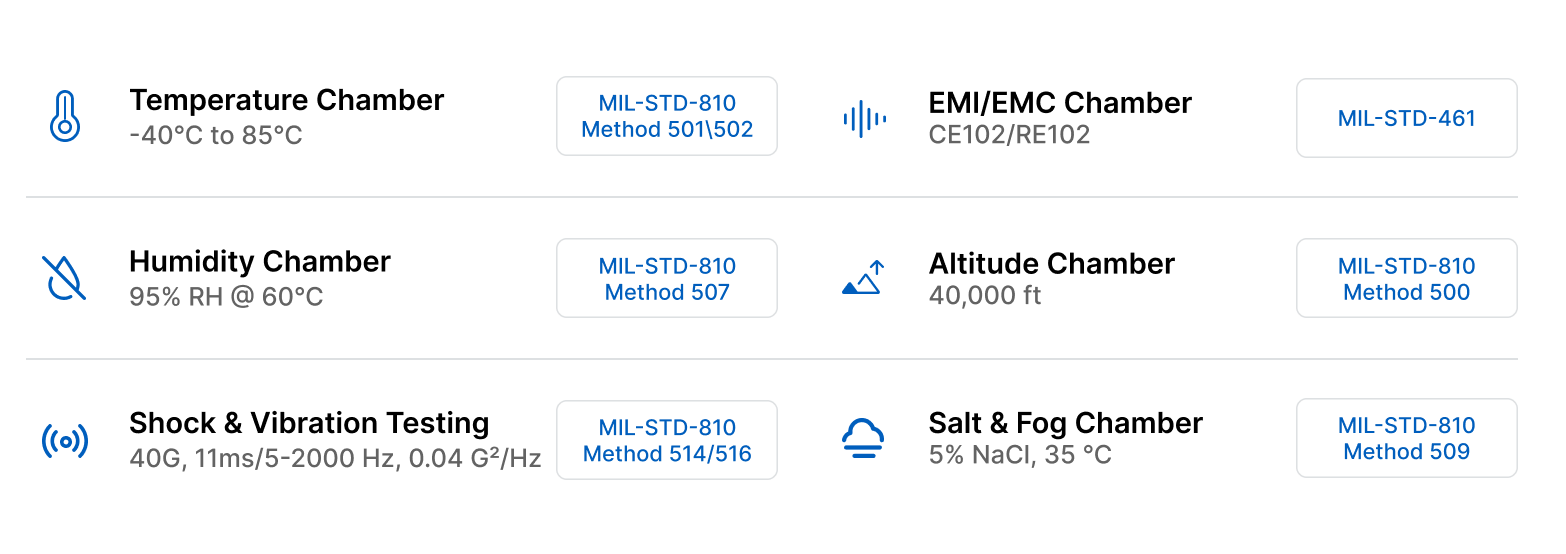

✔ Validate environmental operating conditions

Temperature range

Vibration profile

Humidity exposure

Contaminant exposure

Duty cycle and load variability

When requirements are architected rather than simply documented, downstream integration becomes controlled instead of reactive.

At Core Systems, structured traceability reduces interpretation gaps that often surface late in the program lifecycle.

Most integration instability begins at interfaces.

Not components.

Interfaces.

✔ Document interface control specifications early

Power characteristics

Signal thresholds

Data protocols

Mechanical mating tolerances

Thermal transfer paths

✔ Simulate real-world operating conditions

Model full system behavior under peak load conditions and environmental stress.

✔ Validate legacy compatibility assumptions

Legacy systems introduce invisible constraints. Early validation prevents field-level surprises.

Core Systems engineers integration at the system-of-systems level. This ensures components do not merely function independently but perform reliably together.

When interface assumptions are replaced with structured validation, integration friction decreases dramatically.

In regulated industrial sectors and defense-aligned environments, compliance must shape design decisions from concept phase forward.

✔ Map applicable standards at project inception

Industry standards

Customer specifications

Safety requirements

Environmental regulations

✔ Architect compliance into system design

Safety margins must be structural, not corrective.

✔ Conduct pre-certification validation reviews

Core Systems integrates compliance mapping into architecture rather than treating it as a late-stage audit. This reduces redesign cycles and accelerates certification pathways.

When compliance is embedded early, deployment confidence increases.

Systems rarely fail in ideal conditions.

They fail in real conditions.

✔ Model vibration, shock, and load variability

✔ Evaluate thermal management under sustained operation

✔ Validate power stability under fluctuating supply

✔ Assess signal integrity in high-noise environments

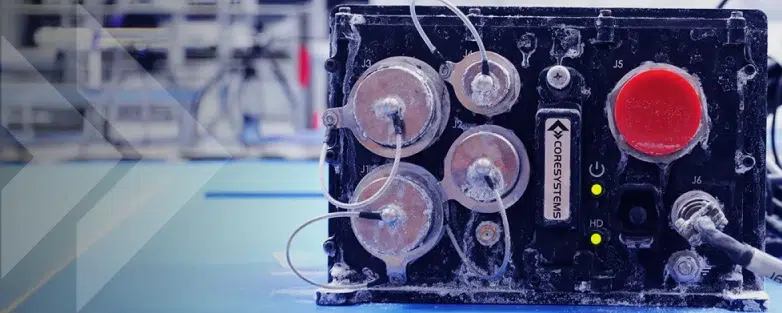

Our experience in defense-grade applications reinforces a simple truth.

If a system performs under worst-case conditions, it performs in standard environments with confidence.

Core Systems applies this philosophy to industrial programs where uptime and reliability are operational priorities.

Phase 5: Cross-Disciplinary Validation Checkpoints

✔ Conduct multi-discipline design reviews

✔ Confirm operational team sign-off before final design lock

✔ Validate maintenance accessibility and service pathways

✔ Review risk register before integration begins

When teams align early, late-stage friction decreases.

Predictability becomes engineered rather than hoped for.

Before commissioning, confirm the system is truly ready.

✔ Validate system-level performance under simulated field conditions

✔ Confirm documentation accuracy matches final configuration

✔ Conduct failure mode scenario walkthroughs

✔ Confirm contingency procedures

Core Systems views deployment readiness as a systems verification milestone, not a schedule checkpoint.

This distinction protects timelines and reduces exposure.

The cost of correcting a design issue increases exponentially as a project advances.

Concept phase adjustments are manageable. Integration phase corrections are disruptive. Field-level corrections are expensive and reputationally damaging.

By applying structured integration discipline early, organizations shift from reactive correction to engineered reliability.

You move from managing problems to preventing them.

That shift changes outcomes.

Core Systems specializes in complex industrial and defense-aligned system integration where reliability is non-negotiable.

Our approach combines:

Structured requirement traceability

System-of-systems interface validation

Compliance-embedded architecture

Environmental stress modeling

Cross-functional integration discipline

The result is reduced redesign cycles, stabilized deployment timelines, and systems that perform reliably under real-world conditions.

When integration is engineered intentionally, performance becomes predictable.

And predictability is what protects operations, contracts, and reputation.